Colorado Sugar Beet History & Architecture

Show on map

Show on map

By Jonathan H

The Longmont Sugar Refinery, once one of the Great Western Sugar Company’s largest factories — shuttered in 1978 (photo copyright Jon Haeber).

Editor’s Note: Yes readers! Once again, I’m bringing you a special series. This one’s about the sugar industry in Eastern Colorado. There are three parts. This is part one. Stay tuned for parts two and three. Enjoy!

In Colorado there is a linear north-south collection of abandoned skeletons following the railroads outside of Denver. These brick edifices are decaying reminders of Colorado’s agricultural renaissance. Bricks collapse from four-story parapets and railroads are buried in weeds and detritus, but behind the decay and overgrowth is the history of the greatest sugar magnate in American history: The Great Western Sugar Company.

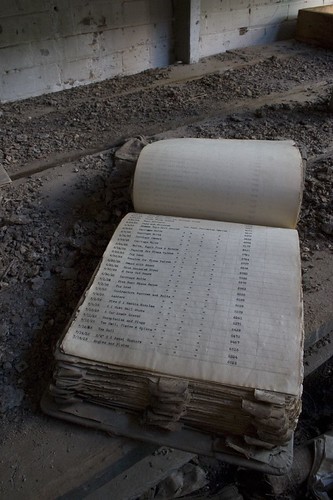

This is a ledger book from the Great Western Sugar Co. Eaton factory. Eaton is named after the tenth governor of Colorado, Benjamin Eaton, who was instrumental in getting the irrigation infrastructure set up that would later serve the beet industry well (photo copyright Jon Haeber).

These massive brick buildings are like nothing I’ve seen in my life. Early in Colorado’s history, the vast expanse of barren land was considered a desert. Famous New York Times Editor, Horace Greeley, described the Colorado plains as a “land of starvation.” This didn’t stop Greeley from endeavoring to establish a utopian colony there. His plan funded the beginnings of place of high moral standards and temperance. Never one to shy away from self-promotion, the utopian colony was named “Greeley.” After the Land Grant Act of 1862, thousands of families flocked to the Colorado plains in search of land worth subduing (in a biblical sense).

At first, wheat was the cash crop, but disaster stuck in the 1890s when the price of wheat plummeted and this bread basket of America needed a new boon basket — beets would be Colorado’s salvation. By 1900, there were brick buildings arising to process the growing influx of beet from the fields. The citadels of these towns had become tall, brick smokestacks spewing steam and spitting out refined sugar.

The Ecology of Growing Sugar Beets

There are only a few places in the world perfectly suited for the sugar beet horticulture. Sugar beets require a specific balance of light, minerals, and water in order to produce a minimum of 12% sugar content by mass — and this balance must follow a specific seasonal schedule. The plains along the Front Range of Colorado had this balance unlike anywhere else in the world. In fact, the balance was so perfect that some areas featured an alarming 17% sugar content by mass.

A young man sits near a truck bed stacked with sugar beets from Northern Colorado, ca. 1915 (courtesy Denver Public Library)

All the Front Range needed was water. That’s where Benjamin Eaton had come in. As a massive landowner, he served as one of Greeley’s first officers of the utopian Greeley colony. Eventually, though, the utopian vision was thrown out the window and dollar signs began appearing in the eyes of the capitalists.

The American Sugar Refining Company headed by robber baron H.O. Havemeyer had incorporated in 1891. Local growers of the utopian proclivity began to accept the capitalist emergence. So says the Jan 15, 1903 New York Times: “It is believed in Colorado that the American Sugar Refining Company has acquired such a large interest in the beet sugar business, either directly or indirectly, that it controls it.”

By 1903, the capitalists had thoroughly gained their ground, and thus the vast amount of money necessary to build the factories flowed in. The factory in Longmont was designed and built by the Kilby Manufacturing Company of Cleveland, Ohio. The bricks for it were provided by contractors Edward Seerie and Frank Hill of Hill & Seerie — who also provided the bricks for Denver’s Sough High School. Longmont Sugar cost one million dollars to construct — an astronomical sum for any project in the early 1900s.

Construction of the Longmont Sugar Refinery, ca. 1910 (courtesy Denver Public Library)

Only two years after construction, the newly formed Great Western Sugar Company had taken over the Longmont factory. In a few years time, the company had retained control of 15 factories along the Front Range. By 1920, Sugar was Colorado’s mainstay — the value of its harvest had multiplied to 20 times its 1900 level.

Please continue following Bearings, or subscribe to its RSS in order to continue following the incredible story of sugar in Colorado. Stay tuned for parts two and three.

Reddit!

Reddit! Del.icio.us

Del.icio.us Digg

Digg StumbleUpon

StumbleUpon Technorati

Technorati Blinklist

Blinklist Furl

Furl

Pingback: Bearings » Blog Archive » Steam Power in Colorado’s Sugar Factories

Pingback: Bearings » Blog Archive » Bearings’ Presidential Endorsement: Barack Obama

Love the blog, if i may ask, what software are you using? how much does it cost? where do you get it? If it’s not a secret email me some details wouldya?

thanks in advance!

hey dud ethat is very cool

hdrhwdhcgjhsdcjhjds nice dude ……………………………………………………..

you are veryy nice!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!>……………….

ur c ute 2

The place is haunted. From first hand expierience. If you have any information on such subject email me

Beautiful photos! My family was associated with the sugar factories from their earliest years. I grew up hearing the names of those early pioneers who started and fostered the industry, then went to school with their grandchildren. Of my relatives, we have over 100 years working in/with the beets.

It breaks my heart to see the beautiful old buildings crumbling and an institution being forgotten.

The industry put food on the tables and clothes on the backs of my family during some pretty tough times. My mother was born at home as the screaming noon whistle blew and her mechanic father came home on the trolley for lunch. He started at the then new factory, was there through 2 wars, retiring after the closure.

My great grandfather was doused with molasses when his emptied beet wagon was jerked by nervous horses while loading the sticky goo on beet pulp destined to feed the cattle at home. (I wondered if the young man in your photo of the beet wagon may have been a relative.)

When desperate for a job, I went to the factory and was hired only to commute with my co-workers striving to make a living for themselves and support families and extended families in Mexico. Often, men waited in lines at the time clock at shift change in order to be hired when openings occurred.

Early “campaigns” gave the workers 12 hour days for the season after the beets were harvested until the last beet was processed. The rest of the year they could work in the fields planting/thinning/weeding and harvesting the beets or, the lucky ones, stayed on to perform maintenance or complete the process of turning the juice into pallets of sugar. It was a dirty, tough, and risky business. Hard hats did not come into use until the 1960s. Hot steam, cold water or sticky juice was everywhere, especially on the metal steps. It took real guts and caution to climb the ladders on the tanks or look down from 300 feet while getting samples readings. Four AM was the turn of the night. If you could stay awake on the first night of a ‘graveyard’ shift, it was downhill from there.

But, there was work when the nation was in a depression. There were groceries during the dust bowl. There were scholarships for their children. There were opportunities for jobs and related industry for the community. I followed my grandfather’s example, putting sugar in his tomato juice and on cottage cheese as he told me we had to “keep Great Western running”. Even with my adult knowledge of the situation, I felt we had failed him when the company went bankrupt in 1985.

As he was getting on in years, on holiday evenings after our family dinners, I drove grandpa on his yearly Christmas or Thanksgiving visit to the men working. Sometimes he would take a pie or some plate of goodies to share with whom ever was on shift at the factory in a nearby town where the beets were still being processed. I heard the names and stories of those men (and women) that pioneered and powered the industry. All the time I thought I was doing him a favor, it was an education for me and experience I will treasure.

My grandson was born in the “shadow of the factory stack”. I took him to what has become of the Fort Collins office complex, now part of the City of Fort Collins. Photos of the old factory were all around. The original bricks could be seen as well as some of amazing architecture. Loveland boasts of a local Sugar Factory museum. Guess that is next on my list to visit. I wonder if grandpa’s picture is there. Maybe there is a shot of myself or of co-worker or friends as we toiled, shared dinner pail meals, or kept each other alert during the late shifts. Many of them are gone just as grandpa and the others from the many years.

Yes, I have no doubt their spirits roam the ruins and old buildings. Don’t worry. They are just those brave workers still on shift or waiting at the time clock. Wave hello or tip your hard hat, and maybe take them a piece of pie.

To whom it may concern:

My father and I are attempting trace our family history. We know that my great grandfather was an executive in the sugar beet industry in Denver. His name was Charles Luff.

I was wondering if the above mentioned company was the one he may have worked for. Can you tell me how I might find out? It would have been between 1890- 1920 we think.

Any help would be great!

yes, this place is haunted! Seeing a picture of it gives me the creeps. what happened there?

I Have alway been very curious about the history and hauntings of this factory. I grew up here in Loveland and I would love to know more if you have any actual hauting stories about this place i would love to read them

How did you get permission to get onsite to take the above photographs?

Can anyone help me locate a Colorado supplier of Molasses and Sugar? Thanks!

Thank you